SNCF LGV+ project

Installation of a Wye configuration system as part of the LGV+ project to modernize the Paris-Lyon high-speed line

Implementation of a Y-system to modernize the LGV Paris-Lyon line

Brief description

The Paris-Lyon LGV is the oldest and busiest high-speed line in France. At peak times, the line quickly reaches saturation. SNCF’s strategic LGV+ project aims to improve traffic flow and to increase the running capacity of the line.

The projected works include modernizing signaling equipment. This involves running a large number of test campaigns, without interrupting commercial service.

To facilitate these test campaigns, SNCF Réseau was looking to install an innovative switching relay which would allow them to switch campaign signals between the old substation and the new substation quickly, easily and safely.

The solution SCLE has developed has been approved by SNCF DGII DTR GE SF Produit.

Our solution included :

- Development in conjunction with SNCF Réseau of a simple, modular Wye configuration system with a small footprint.

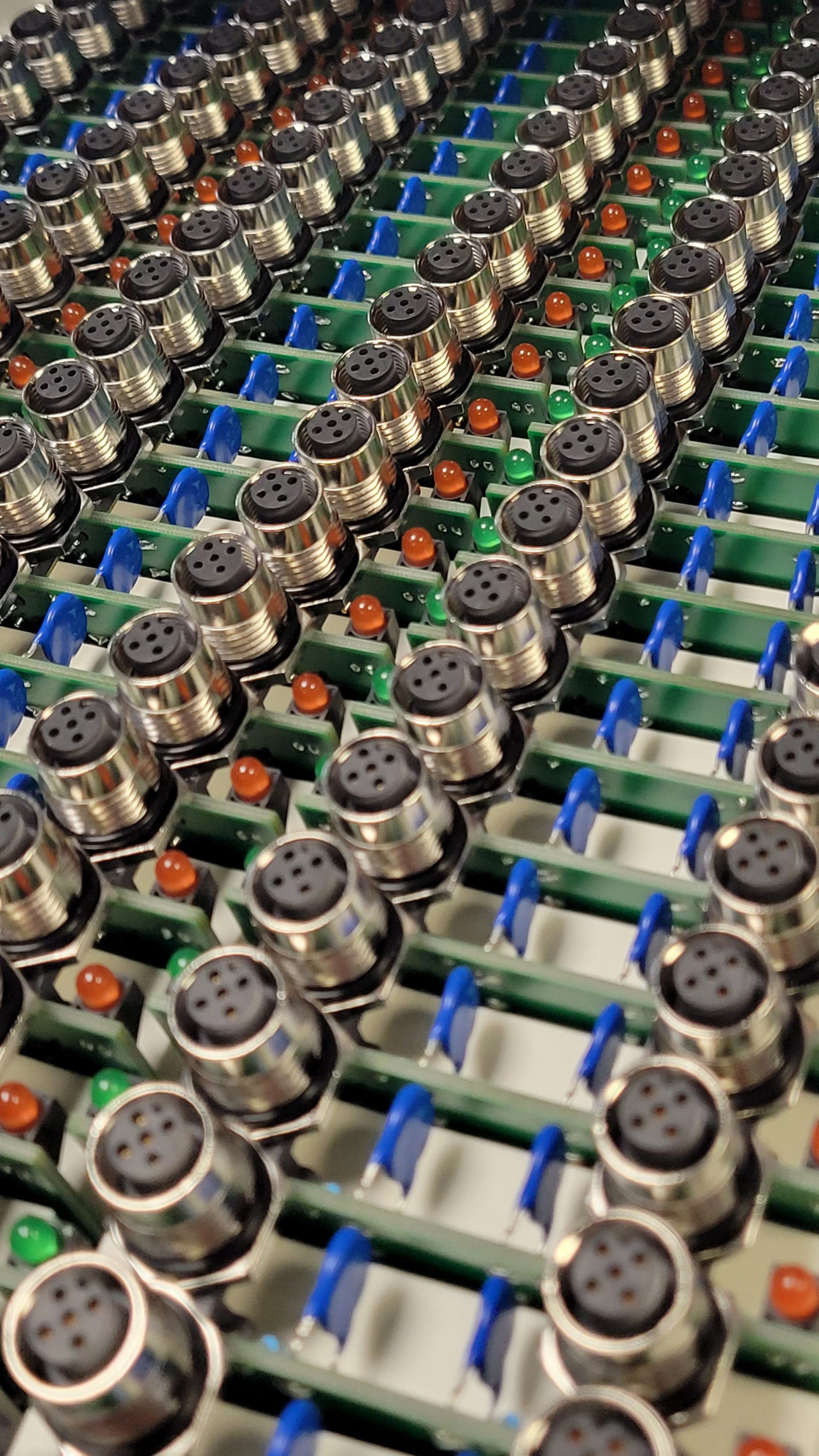

- Design of a technical platform installed directly on the ES8 terminals connected to the signals.

- Design of a switch, connected directly to 4 technical platforms, which flips the signals between the old station and the new station.

- Design of a control box, which can be easily connected by cable to the switching relays, to control them. This box displays the state of the switches and can control up to 120 devices.

- Design of a test box used to display and control the state of the switches.

- Design of a dedicated transport case to protect and store the equipment.

- EMC tests carried out at SCLE.

- Field tests and validation on the Marne-La-Vallée signal box.

- Production of all elements at our Marseille agency.

Challenges

- Set up and conduct test campaigns on time and in completely safe conditions

- Simplify space-saving solution.

- Ensure the Wye-system was easy to use

- Adapt system easily during test progress

Benefits

- Saves time during test campaigns

- Small footprint and modular

- Simple old substation/new substation switch system

- SIL2 system with instant display of relay switching status

- Removable, reusable and easily transportable system

Keys figures

- 1 year development project

- 52 800 technical platforms

- 13 200 switching relays

- 180 control boxes

- 220 carrying cases

- 1.5 years of production

- 16 workstations equipped at the end of 2022

- 42 workstations to be equipped during 2023

Our certifications